Basic Design:

I've chosen to go with a "barrel-ponics" system for the simple reason that these barrels are free. These barrels, when cut in half, are 28cm deep. This is less than the 30cm which appears to be the optimum depth for grow bed containers, but after seeing a number of barrel-ponics systems on the web that work quite well, I decided to go ahead with them.

After looking for something that could serve as a fish tank, including finding and getting quotes from a local fiberglass tank-maker, I've chosen to build a cement tank on site.

The fiberglass tank was very expensive, and the design was not optimal. A cement tank has one major disadvantage, which is it cannot be moved, but it's cheap to put up and I can design it exactly the way I like.

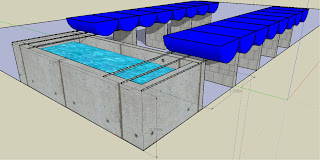

Above is the basic plan. The tank will easilly hold up to 1,600 liters. According to the 1:1 growbed:tank volume rule of thumb, that will be enough to feed 1,600 liters worth of grow-bed volume. These barrels hold approximately 200 liters each, so cut in half, that's 100 liters per barrel, and 16 barrels in total are necessary.

I plan on arranging them in two rows of 8, and supporting them ontop of metal 1" pipes resting accross cement pedestals.

Below are some pictires of the basic set-up coming together.

This is the recently built roof that will protect the AP system. The small structure within the enclosed area is my old germinating green house/nursery. I'll leave that there for now until I get the larger area fully enclosed, at which point I will not need a second enclosed structure.

Cement block pedestals to hold barrels.

Fish tank. The pipe on the right is the return for the draining system. As I later discovered, it is much better to have a separate drain pipe for each grow bed. Multiple grow beds draining into the same drain pipe are a challenge. The water draining out of any one grow bed seals the system. Air inside bell siphons of grow beds that are still filling will not be able to escape, and so the vacuum fails to form. I suppose there could be a way around this, by creating some sort of air escape between each siphon and the drain pipe, but after looking at all the extra plumbing that would require, in addition to not knowing for sure if it would even work, I decided to go with separate drain pipes for each bed. I'll post pics of the blown-out fish tank wall and new drain pipes when that's done.

The barrels cut like butter with a jigsaw. Here, I've called them all together for a meeting to explain to them their new role in life :)

Tanks arranged in row 1. I'll be changing those wood boards to 1" steel pipe just as soon as I get the pipe delivered. Also, I'm going to start the system off with 1,000 liters and build the second row after the system has begun to stabilize.